Process Materials for Electronics Assembly

Indium Corporation is a premier global materials supplier for electronics assembly, semiconductor assembly, thermal management, and many specialized assembly applications. We offer solder materials in over 300 alloys. With the strongest tech support in the industry, Indium Corp stands out as a technology development partner. Indium solders are formulated and manufactured in the USA, with manufacturing facilities for time-sensitive products placed throughout the world, to support your manufacturing on a global scale.

Please contact Creyr Innovation for assistance matching an Indium material to your manufacturing requirements.

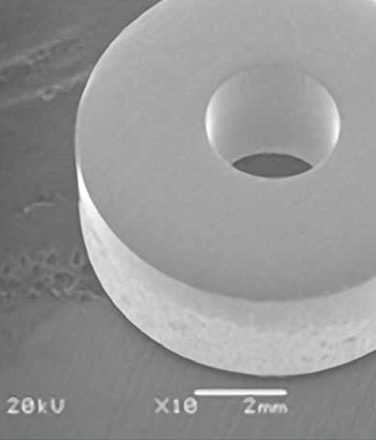

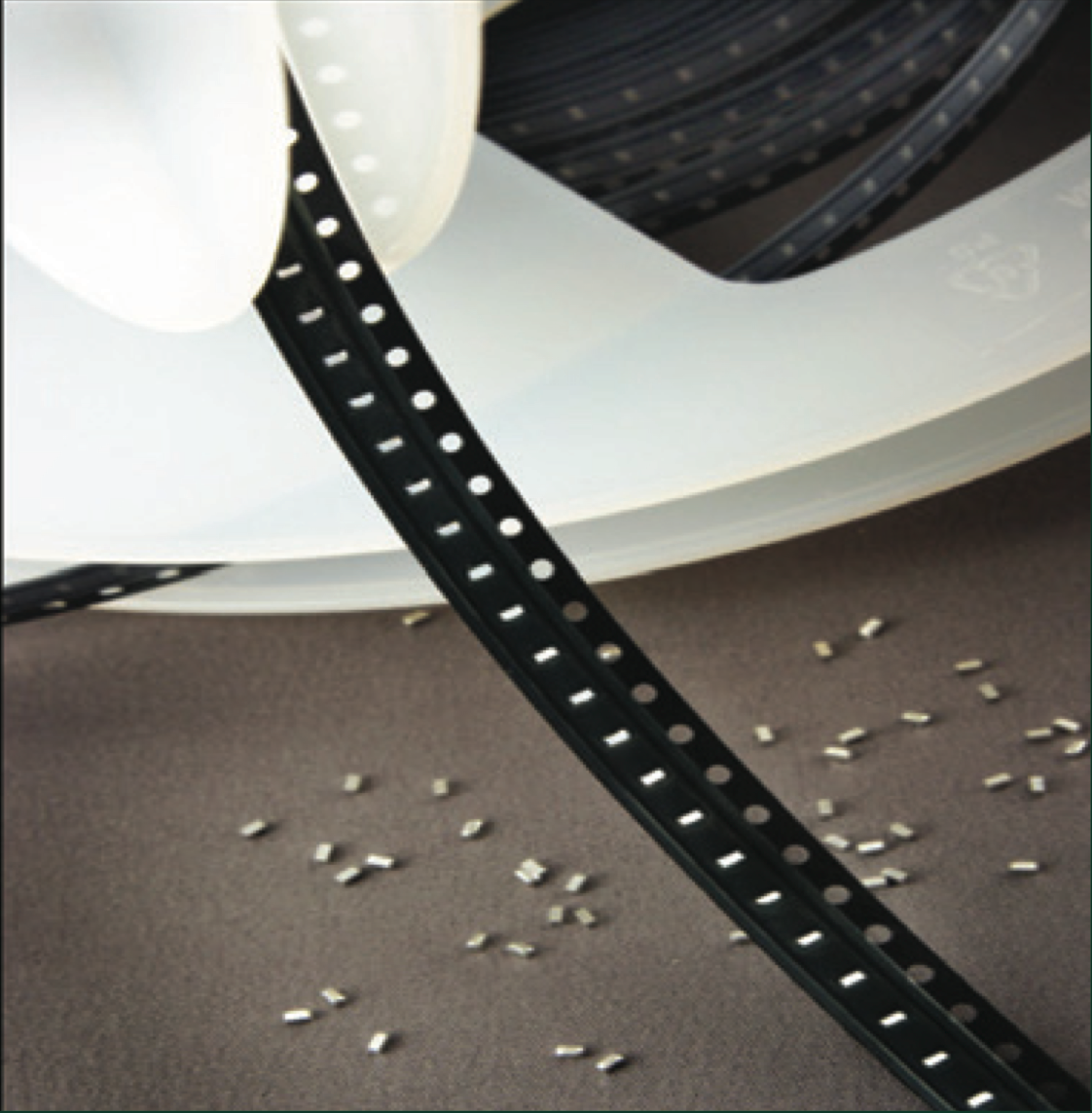

Solder Preforms & Engineered Solder Forms Info

Indium offers solder preforms, wire, ribbon, and spheres in the widest variety of alloys available. Our state of the art manufacturing facility and proprietary manufacturing techniques provide the highest precision for sensitive applications.

Semiconductor & Hybrid Assembly Materials Info

Indium offers a full line of materials supporting semiconductor packaging, including die attach wire and paste, solder spheres, bumping pastes, package on package (PoP) pastes, and fluxes for ball attach, flip chip, PoP, and more.

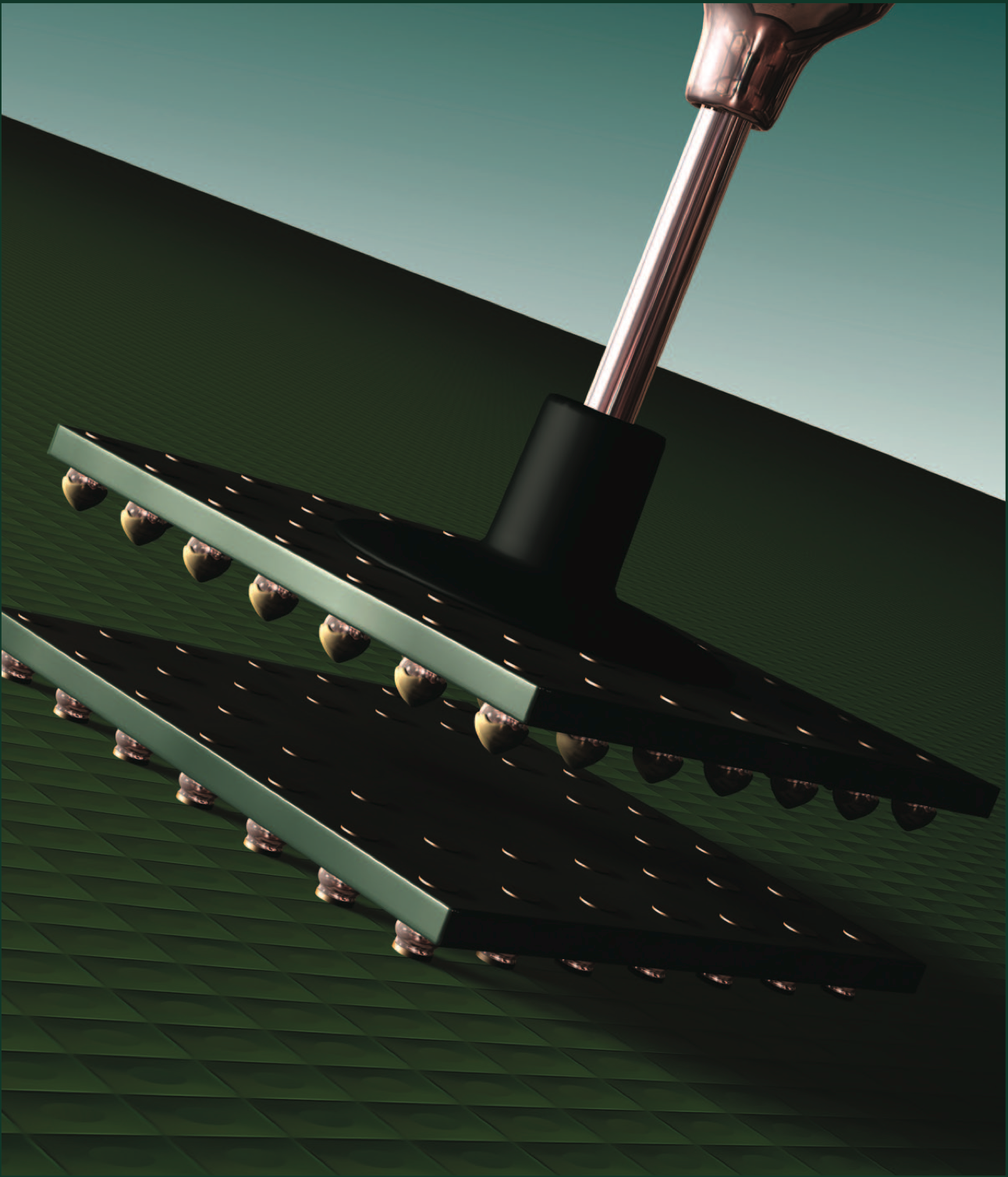

PCB Assembly Materials Info

Indium Corporation solder pastes have long been the work horses of the PCB assembly industry. Indium Corp’s research and development has remained on the forefront of assembly technology, leading the industry in answering soldering changes such as Pb-Free, small scale packages, high speed printing, area array component warpage (e.g. BGA), flush mount components (QFN/LGA), package on package, and more.

The Indium Corp suites of PCB assembly materials also include solder wire, tac fluxes, solder fortification preforms, wave solder, and wave solder fluxes.

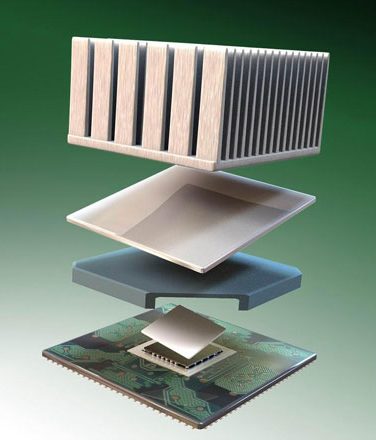

Thermal Interface Materials (TIM) Info

Indium’s line of high-end thermal interface materials delivers superior performance over time. As soft metal alloy thermal interfaces (SMA-TIM) products are made of metal, they cannot experience pump out problems even under power cycling. The Heat-Spring® material, which does not contain silicone, will conform to surface disparities over time, thereby reducing thermal resistance through the life of the TIM. Due to its solid state, the SMA-TIM also resists bake out.

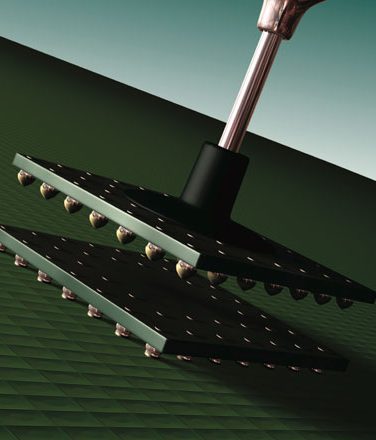

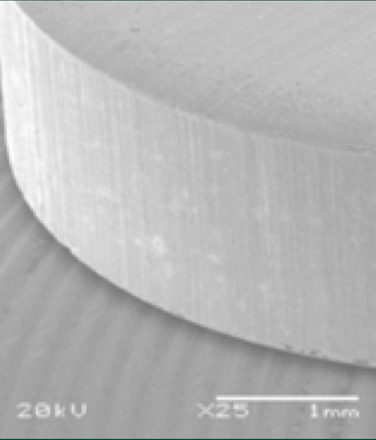

Heat-Spring® Info

Many applications call for TIM that can easily be placed on a chip, on a lid or perhaps just against a heat source and a cooling solution contact plate. We developed a metal TIM which would work as a compressible Interface Solution for such an application. Our pressure range is 35psi to 100+ psi.

An SMA-TIM made of indium offers uniform thermal resistance at lower applied stresses in compressed interfaces. The malleability of indium minimizes surface resistance and increases heat flow. Our patented Heat-Spring® technology will further reduce the thermal resistance.

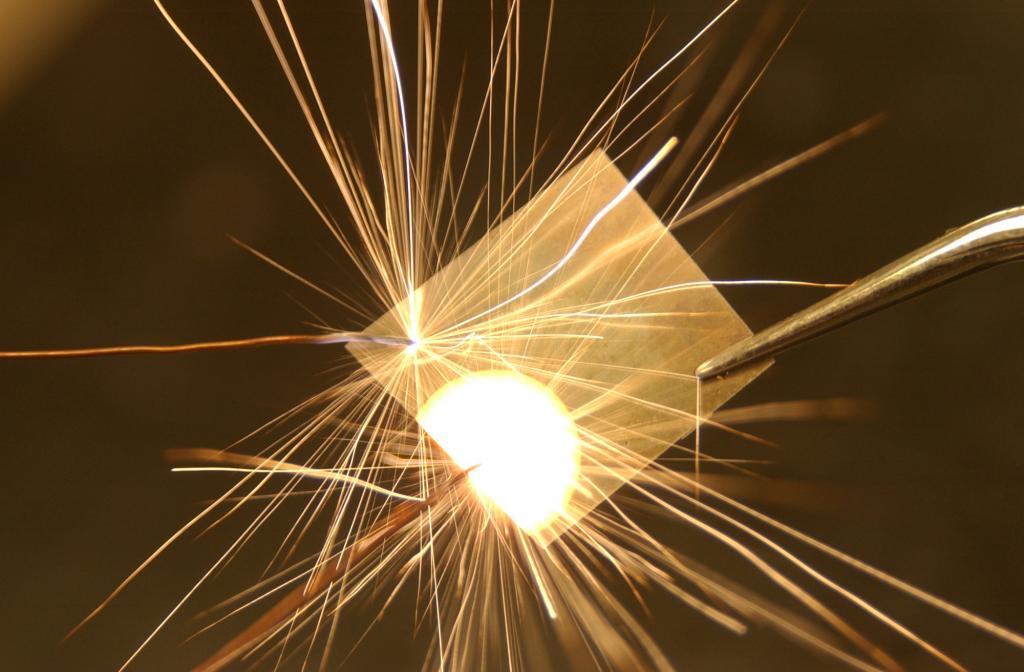

Nanofoil Info

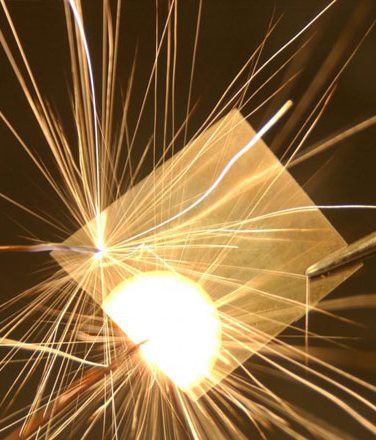

Indium Corporation manufactures NanoFoil®, a nanotechnology material that delivers energy in a controlled and precise manner for joining, energetics and heating applications.

NanoFoil® is a reactive multi-layer foil that provides instantaneous heat for a variety of applications in many industries (semiconductor, aerospace, automobile, electronics, biomedical and defense markets). NanoFoil® is a predictable, controllable and affordable material that is industry accepted and proven to lower manufacturing costs while providing repeatable and reliable bonds and reactions.

Watch NanoFoil in action

For a NanoFoil solution to your technology requirements, please contact Creyr Innovation.

Contact Creyr Indium