Thermal Warpage & Strain Metrology Systems & Services

We offer imaging equipment, and/or testing services at our Atlanta laboratory.

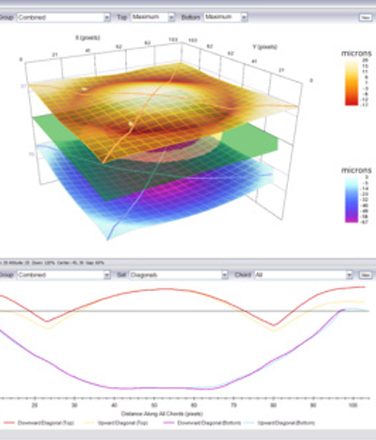

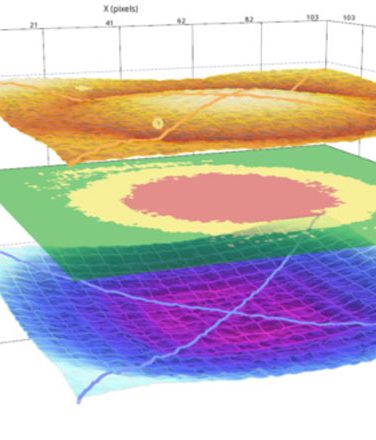

Akrometrix systems provide accurate measurement of warpage, bow, and twist of materials, at processing temperatures (reflow, cure), and at any moment in time. Akrometrix software provides both recording and analysis features, allowing for analysis not just of the individual materials, but of the predicted interface between them, at any temperature. This is invaluable for determining the unique coefficient of thermal expansion characteristics for wafers, components, PCBs, and other assembly materials, assure reliability in manufacturing and usage.

Akrometrix Imaging Technologies:

Shadow Moiré

Digital Image Correlation

Digital Fringe Projection (DFP)

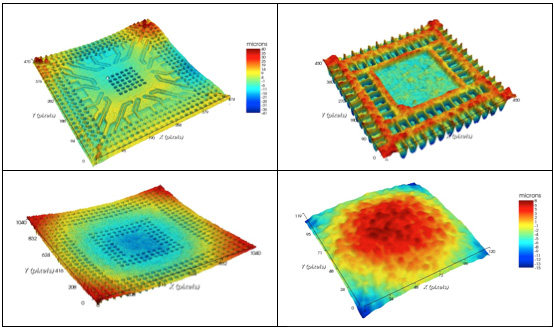

Common Applications for Warpage Measurement

Semiconductor Assembly and Test

PCB Fabrication

Electronic Assembly

OEM/ODM

Electronic Materials and Passive Components

Package on Package (PoP)

Sockets

PCB Global and Landing Areas

Components – BGA, IC, CSP

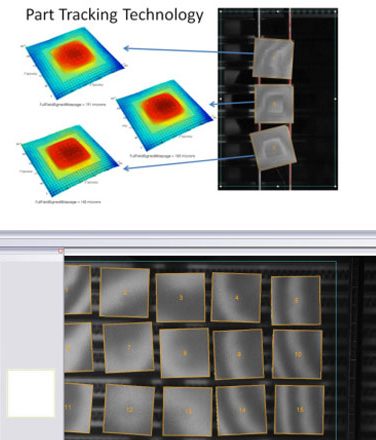

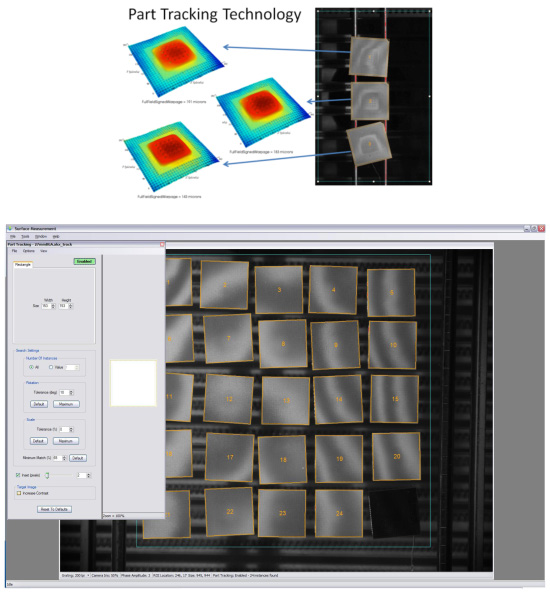

High Volume Testing

Akrometrix Measurement Systems:

Thermoiré AXP Platform

TherMoiré technology can simulate your thermal processing and operating environment conditions, while capturing a complete history of out-of-plane displacement behavior. Applying this critical information to form – or achieve compliance for – component/substrate behavior allowances (i.e. warpage specifications) can directly impact level I and level II assembly yields and enhance product reliability.

- TherMoiré In-Process Warpage Measurement Systems

- Dynamic Temperature Profiling – temperature ranges from -50°C to 300°C

- Modular Metrology – Shadow Moiré, Digital Image Correlation, Digital Fringe Projection

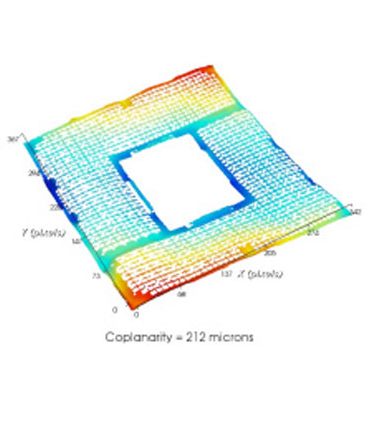

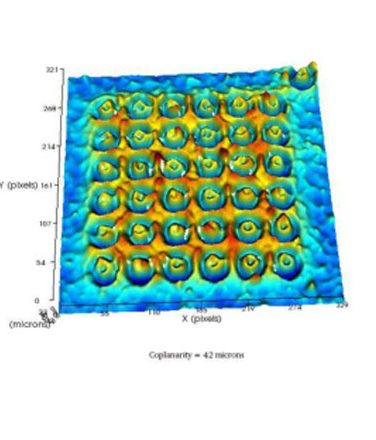

- Automated Analyses – Bow, Twist, Coplanarity, Signed Warpage, CTE, Surface Tilt, etc.

- Data Management – Centralized database tools for production monitoring, trending and customer conformity/assurance requirements.

CXP Platform

The CXP (Convection Expandable Platform) is a low cost, stand alone equipment primarily targeted at the EMS and PCB Fab Market. The CXP uses the Digital Fringe Projection (DFP) technique to measure a field of view of 64x48mm with a measurement resolution of 5 microns. The CXP use the same Studio software used to run the Akrometrix TherMoiré platforms.

The CXP uses a convection oven for heating and cooling and includes a 2MP camera and projector for DFP measurements. The CXP oven can hold samples up to 300x300mm in size and the 64x48mm field of view is movable around the full oven 300x300mm field of view through a sliding gantry.

The CXP provides a cost effective solution for customers looking to adhere to the IPC 9641 industry standard concerning measuring local board warpage.

Testing Services

Akrometrix offers testing services in our Atlanta-based laboratory for:

- Flatness, warpage and coplanarity of PCBs, substrates, ICs and package samples over a temperature profile such as reflow or thermal cycling.

- In-plane deformation (strain) measurement and CTE measurement

- Form factors down to 2 mm and up to 600mm.

- PCB/substrate characterization at temperature

- Pb-Free processing implementation

- Validation of Finite Element Modeling (FEM)

- Supplier performance and conformity monitoring

- Evaluation of different materials and constructions

- Failure/defect analysis

- Machined component flatness check